XMA Rotor - Wireless DAU for Helicopter Rotor Heads

XMA Rotor - Wireless DAU for Helicopter Rotor Heads and Aircraft Propellers

Introduction

45 years of experience in flight test instrumentation and telemetry solutions have enabled Safran Data Systems to design and build technology that performs reliably in the most challenging environments and meet evolving needs in the industry. In working with Airbus on the RACER project, Safran have developed the XMA ROTOR, a fully wireless and modular data acquisition system for rotor heads.

The Safran Data Systems XMA-ROTOR provides high performance XMA modules technology built in a mechanical housing dedicated to helicopter rotor head instrumentation. The XMA-ROTOR replaces legacy slip ring technology offering a full wireless/contactless link between the rotor and the stator. Power is transferred via inductive coupling. Acquired data, health monitoring information, configuration data and synchronization signals are transferred over a bi-directional radio link. The XMA-ROTOR, as a standard XMA stack, is scalable and can host from 2 to 16 XMA wireless modules of various kinds: analogue, digital, discrete, video…

The XMA-ROTOR is designed to cope with environmental conditions of civil and military rotorcraft. Designed to operate seamlessly with existing flight test systems, the XMA-ROTOR is configured and managed as standard XMA stack and is fully compatible with Safran Data Systems architecture.

Key Features:

|

- Fully Wireless: |

No slip ring, low intrusive and maintenance-free technologyLow EMI pollution and permanent health monitoring |

|

- Easy to Configure: |

Configured and managed remotely by the eZ Software Suite |

|

- Scalable: |

Up to 120 strain gages or accelerometers, or 240 temperatures or any combinations |

|

- Easy to Configure: |

eZ software suite, XML schema (MDL) |

|

- Harsh Environments: |

Built to sustain up to 2500 rpm without additional bracket |

|

- High Efficiency Wireless Power: |

Low EMI pollution and permanent health monitoring |

Configuration:

A stationary inductive power converter and transmitter, cable, and inductive transmission coil, provide power to an inductive reception coil mounted on the rotor head which is in turn cabled to the XMA power supply.

As with the standard XMA, acquisition modules are added to suit the requirements of the test.

Modules:

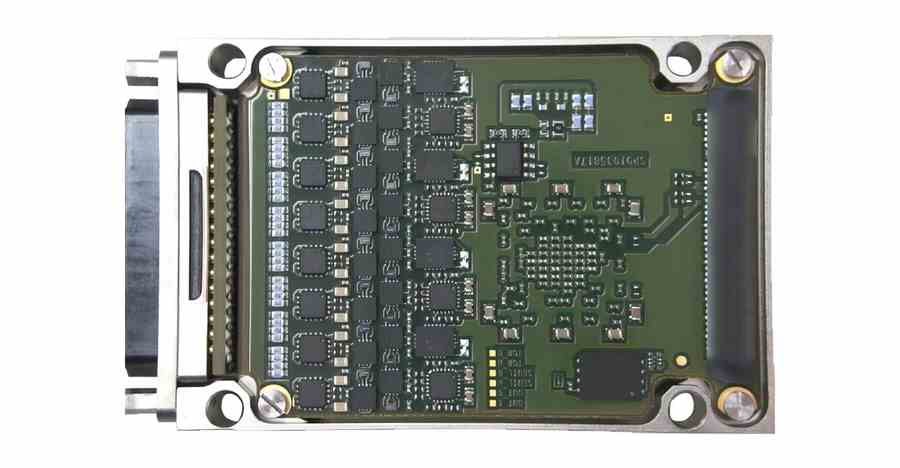

A comprehensive range of modules are available for XMA Rotor, see list on the XMA page. Each XMA modules has a 2" x 3" form factor and incorporate the same form field workable connector for ease of integration in existing flight test networks.

Flight Test Instrumentation Product Menu : μMA - XMA - XMA Rotor - MDR - MDR-GT - XMA-MDR Combo - HyperLink - eZ Software

Request a demo

For more details and to request a demonstration contact Photo-Sonics International.